CNC-Ready Panels & Plates

Rigid Carbon Fiber Sheets

Engineered for Structural Parts & Repeatable CNC Machining

Rigid carbon fiber sheets (CFRP panels/plates) are laminate composites selected when high stiffness, low weight, and dimensional stability are critical. Typical uses include UAV/drone frames, RC chassis, jigs & fixtures, robotics plates, and other precision components that require consistent machining results.

Unlike flexible veneers or cosmetic skins, rigid sheets are built with defined fiber orientation, controlled thickness, and structural UD core options (such as T300 or T700) to support practical load paths and reliable edge quality during cutting and drilling.

For a practical recommendation, share your application, thickness target, and primary load direction.

Why Choose Our Rigid Carbon Fiber Sheets

- High stiffness-to-weight performance for structural plates and panels

- Dimensional stability under load and vibration for consistent assemblies

- CNC-ready laminate for stable machining behavior and clean cut edges

- Piece-by-piece surface inspection for cosmetic consistency

- Custom options for weave, finish, UD core, and layup orientation

- Support for prototypes and production builds

Build Options: Surface, Finish, Core & Layup

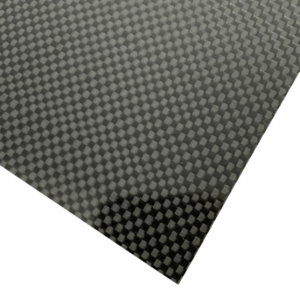

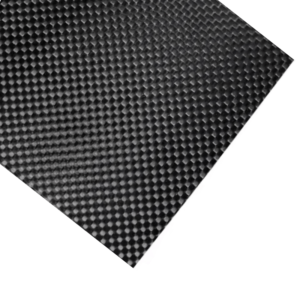

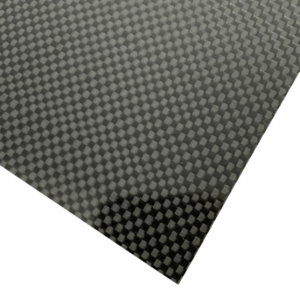

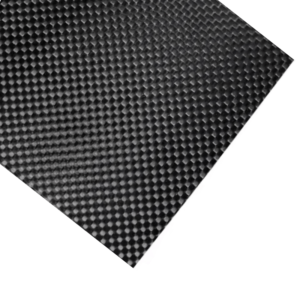

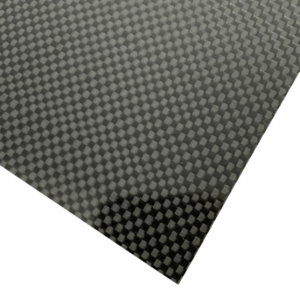

Surface styles

- 3K Plain weave / 3K Twill weave

- Forged carbon (black or color-infused)

- Colored carbon surface options (for visual differentiation)

Surface finish

- Gloss

- Matte

- Semi-gloss

- Spray-painted surface treatment (when a coated appearance is required)

Core (structural)

- UD T300 carbon fiber

- UD T700 carbon fiber

Fiber orientation

- 0° / 90°

- ±45°

- Hybrid multi-axis layups

CNC Cutting & Machining Notes

Rigid CFRP laminates are well-suited for CNC cutting when geometry, tooling, and process are aligned. For better edge integrity and repeatability:

- Use internal corner radii instead of sharp inside corners

- Avoid extremely thin bridges around cutouts

- Prototype first for complex geometries or tight cosmetic requirements

- Send DXF or STEP files for cut-to-size and CNC quotation

Specifications

| Property | Description |

|---|---|

| Material type | CFRP laminate (carbon fiber reinforced epoxy) |

| Thickness range | 1.0–10.0 mm |

| Thickness tolerance | ±0.1 mm |

| Standard size | 500 × 500 mm (custom sizes available) |

| Surface finish | Gloss / Semi-gloss / Matte |

| Surface styles | 3K Plain / 3K Twill / Forged / Colored |

| Core options | UD T300 / UD T700 |

| Fiber orientation | 0°, 90°, ±45°, or hybrid multi-axis |

| Manufacturing route | Laminate consolidation via controlled press or autoclave (per build requirement) |

| Cutting service | Cut-to-size & CNC quoting via DXF/STEP |

Manufacturing & Quality Control

Surface Inspection (piece-by-piece)

Every sheet is inspected on both sides before packing. Checks focus on weave alignment, surface pinholes/void appearance, scratches, foreign particles, resin-rich/lean visual areas, and handling marks—supporting cosmetic consistency and machining readiness.

Applications (by target audience)

UAV / Drone structural engineers

Rigid laminates provide high rigidity and vibration resistance for frames, arms, and plates. Share your load direction and thickness target to align layup selection with real mounting and load constraints.

Medical device procurement / engineering teams

Medical panels often require defined finish requirements for repeated cleaning. Confirm your cleaning method and target finish (gloss or matte). Coated-look surface treatment can be discussed when required.

Automotive performance modification shops

Aero panels should include reinforced mounting zones to handle clamp loads, vibration, and edge stresses. Send your mounting layout to reduce the risk of local crushing or edge damage.

Industrial robotics / machinery designers

For lightweight plates and frames, match fiber orientation to load paths and use cut-to-size/CNC service to reduce assembly time and rework.

Ordering & Lead Time

- MOQ: No minimum for standard options; custom builds start from 1 sheet

- Lead time: 3–7 days

- Files for quoting: DXF or STEP

- Shipping: DHL / FedEx / freight with protective packaging

- Bulk orders: Volume pricing available. Neutral packaging and custom labeling can be arranged upon request.

FAQ

Can you cut custom shapes, holes, or pockets?

Yes. Send your DXF or STEP files for quotation.

What’s the difference between UD T300 and UD T700 core?

Both are UD structural core options. The selection depends on stiffness/strength requirements, thickness, and the part’s load case.

Are forged/colored surfaces only decorative, or can they be structural?

They can be structural. Surface style can be selected for aesthetics while the internal UD core and layup are built for stiffness and strength.

Will CNC cutting cause fraying or delamination?

Edge quality depends on geometry, tooling, and process settings. For complex designs or tight cosmetic requirements, prototyping is recommended.

What finishes can you provide?

Gloss, matte, and semi-gloss laminate finishes. Coated-look surface treatment can be discussed when required.

Which layup is better for torsion-heavy parts like arms or brackets?

±45° layers are commonly used to improve torsional behavior, while 0/90 supports plate-like loads. Share load direction and part geometry for a practical recommendation.

Ready to Start?

Send your required thickness, finish, and files (DXF/STEP) for a fast quote and build recommendation.

Showing 1–16 of 42 results

-

Carbon Fiber Sheet– 1.0mm Thick Plain Gloss

$7.00 – $558.31Price range: $7.00 through $558.31 Select options This product has multiple variants. The options may be chosen on the product page -

Carbon Fiber Sheet– 1.0mm Thick Plain Matte

$7.00 – $558.31Price range: $7.00 through $558.31 Select options This product has multiple variants. The options may be chosen on the product page -

Carbon Fiber Sheet– 1.0mm Thick Twill Gloss

$7.00 – $558.31Price range: $7.00 through $558.31 Select options This product has multiple variants. The options may be chosen on the product page -

Carbon Fiber Sheet– 1.0mm Thick Twill Semi Matte

$7.00 – $558.31Price range: $7.00 through $558.31 Select options This product has multiple variants. The options may be chosen on the product page -

Carbon Fiber Sheet– 1.0mm Thick Plain Semi Matte

$7.00 – $558.31Price range: $7.00 through $558.31 Select options This product has multiple variants. The options may be chosen on the product page -

Carbon Fiber Sheet– 1.0mm Thick Twill Matte

$7.00 – $558.31Price range: $7.00 through $558.31 Select options This product has multiple variants. The options may be chosen on the product page -

Carbon Fiber Sheet– 10mm Thick Plain Gloss

$7.00 – $558.31Price range: $7.00 through $558.31 Select options This product has multiple variants. The options may be chosen on the product page -

Carbon Fiber Sheet– 10mm Thick Plain Matte

$7.00 – $558.31Price range: $7.00 through $558.31 Select options This product has multiple variants. The options may be chosen on the product page -

Carbon Fiber Sheet– 10mm Thick Twill Matte

$7.00 – $558.31Price range: $7.00 through $558.31 Select options This product has multiple variants. The options may be chosen on the product page -

Carbon Fiber Sheet– 10mm Thick Twill Semi Matte

$7.00 – $558.31Price range: $7.00 through $558.31 Select options This product has multiple variants. The options may be chosen on the product page -

Carbon Fiber Sheet– 10mm Thick Plain Semi Matte

$7.00 – $558.31Price range: $7.00 through $558.31 Select options This product has multiple variants. The options may be chosen on the product page -

Carbon Fiber Sheet– 10mm Thick Twill Gloss

$7.00 – $558.31Price range: $7.00 through $558.31 Select options This product has multiple variants. The options may be chosen on the product page -

Carbon Fiber Sheet– 2.0mm Thick Twill Matte

$7.00 – $558.31Price range: $7.00 through $558.31 Select options This product has multiple variants. The options may be chosen on the product page -

Carbon Fiber Sheet– 2.0mm Thick Plain Gloss

$7.00 – $558.31Price range: $7.00 through $558.31 Select options This product has multiple variants. The options may be chosen on the product page -

Carbon Fiber Sheet– 2.0mm Thick Twill Semi Matte

$7.00 – $558.31Price range: $7.00 through $558.31 Select options This product has multiple variants. The options may be chosen on the product page -

Carbon Fiber Sheet– 2.0mm Thick Plain Matte

$7.00 – $558.31Price range: $7.00 through $558.31 Select options This product has multiple variants. The options may be chosen on the product page