Custom Carbon Fiber Parts are engineered to meet application-specific strength, stiffness, and weight targets where dimensional accuracy and repeatability matter. At iKabon, we manufacture CNC-machined carbon fiber components for engineers and procurement teams who require predictable machining behavior and clear design-for-manufacturability feedback.

From prototyping to repeat production, we work directly from customer drawings and functional requirements to deliver carbon fiber parts that are manufacturable, inspectable, and suitable for global shipment.

Carbon fiber machining involves real constraints, including delamination risk, fiber breakout, dust management, and heat-sensitive surface quality. Part geometry, feature placement, and fiber orientation are reviewed during engineering evaluation to ensure stable and repeatable results.

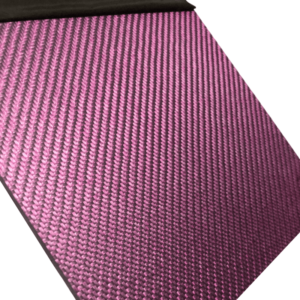

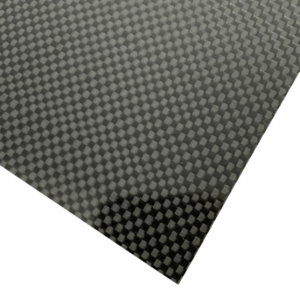

If stiffness and load direction are critical, fiber orientation should be defined in the drawing. If surface appearance is critical, weave style, symmetry, and visible face requirements should be specified to avoid ambiguity during machining.

Drawings should clearly indicate finished dimensions, datum references, and critical-to-function features such as holes, interfaces, and mating surfaces.

When design constraints are unclear, engineering feedback is provided before production to minimize rework and scrap risk.

Dimensional control for carbon fiber parts should align with function rather than applying uniform tolerances. Critical features should be identified on the drawing, while non-critical geometry may allow relaxed limits to optimize cost and lead time.

Inspection methods and verification steps are defined based on project stage and application requirements.

Below is a practical mapping between common applications and suitable carbon fiber forms (sheets/plates, forged laminates, tubes, blocks, and CNC-machined parts). If you share your drawing and functional requirements, we can recommend a practical laminate intent and machining approach before quotation.

Typical priorities are cosmetic consistency, edge durability after profiling, and clean CNC finish on contoured surfaces.

Related products: Forged Carbon Fiber Sheets, Carbon Fiber Sheets / Plates, Carbon Fiber Blocks

Watch components require high cosmetic standards and tight tolerance control at interfaces.

Related products: Forged Carbon Fiber Sheets, Carbon Fiber Sheets / Plates

UAV structures prioritize stiffness-to-weight, repeatable thickness, and predictable in-plane behavior.

Related products: Rigid Carbon Fiber Sheets, Carbon Fiber Tubes, CNC-machined Carbon Fiber Components

Robotics assemblies require stiffness and dimensional stability to maintain positioning accuracy.

Related products: Machining-grade Carbon Fiber Laminates, Carbon Fiber Blocks, CNC-machined Carbon Fiber Components

Tooling plates and fixtures benefit from stable thickness and predictable machining behavior.

Related products: Carbon Fiber Sheets / Plates, Carbon Fiber Blocks, CNC-machined Carbon Fiber Components

Attach your drawing and highlight critical features to receive an engineering-reviewed quotation.

Showing 97–112 of 127 results

At iKabon, we are driven by a vision to revolutionize lightweight construction by making carbon components easily accessible to engineers across the industry.