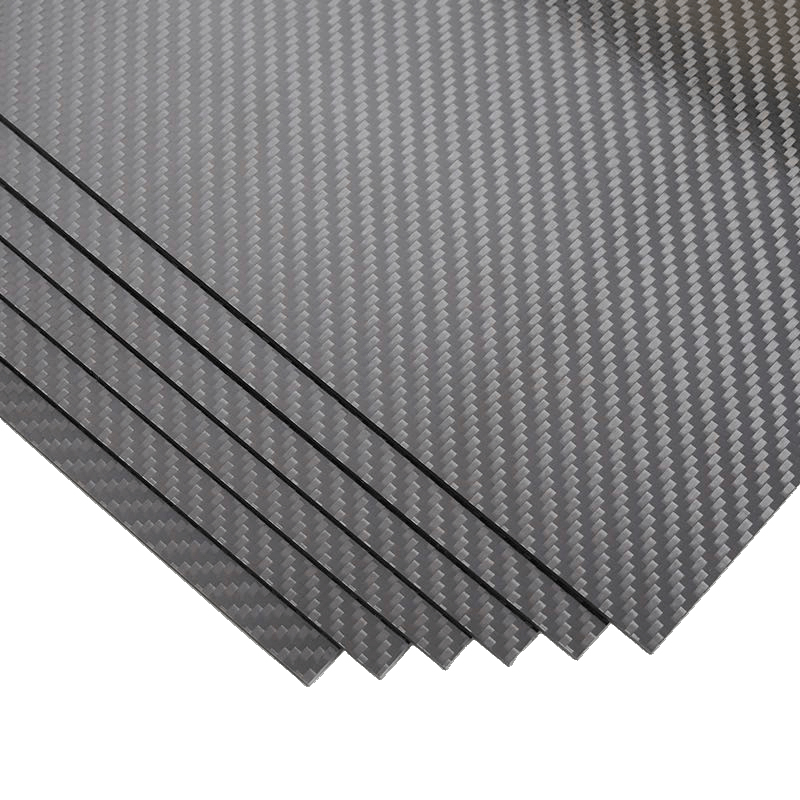

Discover top-grade carbon fiber sheets manufactured using premium raw materials in advanced autoclave processes, guaranteeing a flawless finish, superior quality, and unmatched performance.

Ideal for aerospace and RC applications, our carbon fiber sheets offer exceptional strength and durability.

Customize your order with a variety of finishes and thicknesses to meet all your high-performance material needs.

Explore our exclusive range of colored carbon fiber sheets, meticulously crafted with premium raw materials and cutting-edge autoclave technology to ensure a vibrant finish, outstanding quality, and superior performance.

Perfect for custom projects in aerospace, automotive, and RC hobbies, our colored carbon fiber sheets deliver unparalleled strength, durability, and aesthetic appeal.

Available in a spectrum of colors, finishes, and thicknesses, our sheets are designed to fulfill your specific high-performance and design requirements.

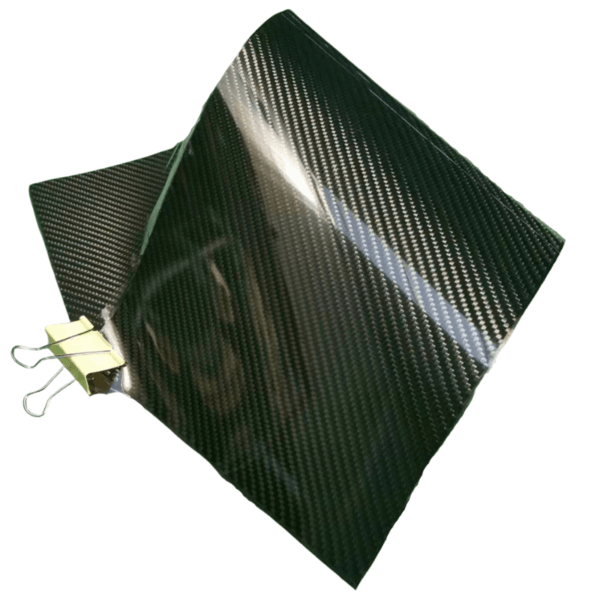

Introducing our flexible carbon fiber sheets, ingeniously designed with advanced composite materials and state-of-the-art manufacturing techniques to ensure exceptional flexibility, unmatched durability, and superior performance.

These sheets are ideal for innovative applications in industries such as aerospace, automotive, consumer electronics, and beyond, offering the unique combination of lightweight strength and adaptability.

Discover the unmatched strength and aesthetic elegance of our forged carbon fiber sheets, expertly crafted using innovative forging techniques and premium composite materials for superior density, strength, and intricate patterns.

Ideal for high-end automotive, luxury goods, and cutting-edge aerospace applications, our forged carbon fiber sheets offer a distinctive look with unparalleled durability and performance.

Tailor your projects with our range of textures, finishes, and thickness options, ensuring your specific design and performance needs are flawlessly met.

Experience the pinnacle of material engineering with our carbon fiber block, meticulously designed with high-density, premium carbon fiber for unmatched strength, durability, and precision.

Ideal for manufacturing, industrial applications, and custom projects requiring the utmost in material integrity and performance, our carbon fiber block can be precisely machined to meet any specification. With its superior thermal and chemical resistance, it offers a robust solution for demanding environments.

Customize your carbon fiber block with a selection of sizes and finishes to perfectly align with your project’s requirements and innovative ambitions.

As a professional carbon fiber sheets manufacturer, iKabon is committed to providing diverse and high-performance carbon fiber solutions. Our carbon fiber sheets are known for their exceptional strength, durability, and excellent appearance.

We manufacture these sheets using high-performance raw materials and advanced processes like autoclaving and molding. We can customize carbon fibre sheets in various sizes, thicknesses, and styles according to customer needs.

Explore our range of carbon fiber sheets, please contact us directly via email if you can’t find the specifications you need in our online store.

In the field of carbon fiber materials, the term “carbon fiber sheets” is sometimes used to refer to “carbon fiber plates”or “carbon fiber panels”. Although these three terms can be used interchangeably in some contexts, each has distinct characteristics and applications.

“Carbon Fiber Sheets” typically refer to thin and flexible carbon fiber materials, suitable for applications needing lightness and flexibility, such as aerospace and high-performance sports equipment.

“Carbon Fiber Plates” are thicker and sturdier, suitable for applications requiring high strength and rigidity, like mechanical structural parts and construction applications.

“Carbon Fiber Panels” usually cover a larger area, applicable in scenarios needing extensive coverage while maintaining lightweight and high-strength properties, such as in vehicle exteriors or architectural facades.

Our high-performance carbon fiber sheets are specifically designed for racing drones and RC Cars, using unidirectional materials like T300 and T700, combined with Toray’s 3K carbon fiber surface material, to ensure optimal strength and durability. These sheets of carbon fibre feature precise layering technology, offering various layup (0°/90°, ±45°, 0°/45°/90°/-45°) to suit different application requirements. Whether it’s the speed and agility needed for racing drones or the strength and durability for RC Cars, our carbon sheets provide exceptional performance and reliability.

We offer specially designed carbon fiber sheets for interior decoration, furniture making, and luxury product design. These sheets are known for their unique textures and beautiful appearance. Our range includes forged carbon fiber, full 3K solid woven carbon fiber sheets , and colored carbon fiber sheets, each adding a high-end, stylish look to your design projects.

In addition to traditional carbon fiber plates, we also provide ultra-thin flexible carbon fiber sheets, with a thickness of just 0.5 mm, perfect for applications requiring high flexibility and mobility. These thin carbon fiber sheets are flexible and lightweight, ideal for high-tech applications like simulated racing cars.

At iKabon, every piece of carbon fiber sheet represents our commitment to quality and innovation. Whether your needs are for high-performance racing equipment or unique decorative finishes, we can provide customized solutions tailored to your industry’s specific requirements. Contact us to choose the carbon fiber sheets that best suit your application and bring excellence to your project.

The variety in carbon fiber sheets is due to differing manufacturing methods, fiber types, resin types, and weave patterns. These variations cater to specific strength, flexibility, and weight requirements for different applications.

Carbon fiber sheets can have several surface treatments, including clear coating, matte finishing, and textured surfaces for improved adhesion. The number varies, but our common options are gloss, semi-gloss, and matte finishes.

Yes, we can customize large carbon fiber sheets as your request.

Yes, we can customize the thickness of carbon fiber sheets according to your project needs. We offer a range of standard thicknesses and can accommodate custom requests.

The suitability of a carbon fiber sheet for your project depends on your specific requirements like strength, flexibility, weight, and environmental resistance. Contact us, we can help determine the best fit.

The largest size of our carbon fiber sheet is 8000mm X 3000mm.

The maximum temperature a carbon fiber sheet can withstand depends on the resin used. Most of our standard carbon fiber sheets can withstand temperatures up to approximately 120°C -180°C (248°F~356°F), but we can customize high temperature materials to withstand higher temperatures.

The cost of carbon fiber sheets varies widely based on size, thickness, weave pattern, and quality. You can check our carbon fiber sheet price from our online shop. Feel free to contact us if you want a wholesale price.

Yes, we offer carbon fiber cutting service since 2013. Just email us the drawings for a quotation.

Cutting carbon fiber sheets should be done with diamond-tipped tools or abrasive cutting wheels. If you want to know more about carbon fiber cutting, just email us. Safety equipment is crucial due to the fine, sharp fibers produced when cutting; a dust mask, eye protection, and gloves are recommended.

At iKabon, we are driven by a vision to revolutionize lightweight construction by making carbon components easily accessible to engineers across the industry.