Introduction

Carbon fiber is a high-strength, lightweight material known for its durability and versatility. It has become increasingly popular in various industries due to its exceptional properties and wide range of applications. Custom carbon fiber parts are tailored to meet specific project needs, making them an ideal choice for numerous applications. This article aims to explain why custom carbon fiber parts are a superior choice for your next project, highlighting their benefits, customization process, and practical applications.

What Are Custom Carbon Fiber Parts?

Custom carbon fiber parts are specially designed components made from carbon fiber material tailored to meet specific project requirements. The customization process involves several stages: design, manufacturing, and finishing. During the design phase, engineers create detailed plans based on the client’s specifications. In manufacturing, advanced techniques like CNC machining and molding ensure precision and quality. Finally, the finishing process includes polishing and applying protective coatings to enhance durability and aesthetics. Custom carbon fiber parts are ideal for various projects, including drones, RC cars, and automotive components, where performance and lightweight properties are crucial.

The Benefits of Custom Carbon Fiber Parts

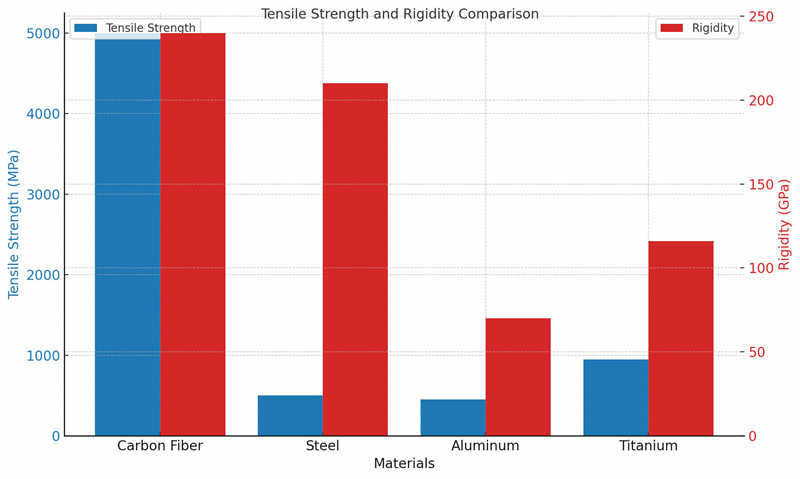

Lightweight and Strong

Custom carbon fiber parts are renowned for their exceptional strength-to-weight ratio. Carbon fiber is significantly lighter than materials like steel and aluminum while offering comparable, if not superior, strength. This makes it ideal for applications where reducing weight is crucial, such as in drones and automotive components, improving speed and fuel efficiency.

Durability and Longevity

Carbon fiber parts are highly resistant to corrosion and wear, making them more durable than many traditional materials. Unlike metals, carbon fiber does not rust, and it withstands harsh environmental conditions without degrading. This results in a longer lifespan for parts, reducing the need for frequent replacements and maintenance.

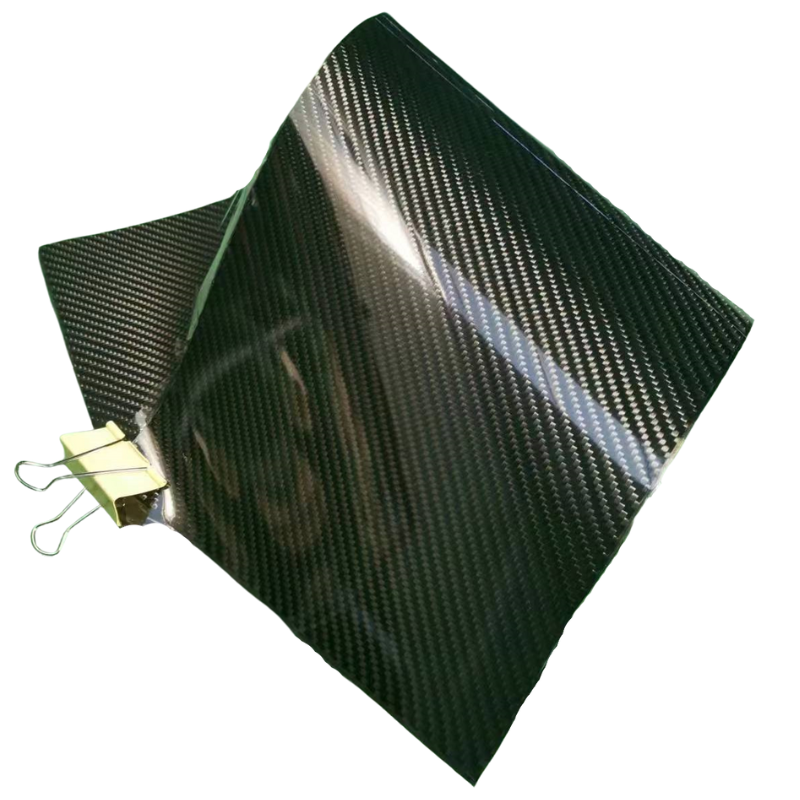

Aesthetic Appeal

Carbon fiber has a distinct, high-tech appearance that adds a sleek and modern look to any project. Customization options include various finishes, colors, and patterns, allowing for unique and visually appealing designs. Whether for automotive interiors or consumer electronics, carbon fiber can be tailored to match any aesthetic preference.

Performance Enhancement

Custom carbon fiber parts can significantly enhance the performance of various applications. For instance, in motorsports, carbon fiber components reduce the vehicle’s overall weight, leading to better acceleration and handling. Case studies and customer testimonials often highlight substantial improvements in performance, underscoring the material’s effectiveness in demanding environments.

The Customization Process

Design Flexibility

Custom carbon fiber parts offer immense design flexibility, allowing them to meet specific project requirements precisely. Engineers can create bespoke designs tailored to unique applications, ensuring that every aspect of the part aligns with the project’s needs. For example, custom carbon fiber brackets for drones can be designed to optimize weight distribution and enhance stability, demonstrating the material’s adaptability to various uses.

Advanced Manufacturing Techniques

The manufacturing of custom carbon fiber parts involves advanced techniques such as CNC machining and molding. CNC machining ensures high precision, allowing for the creation of intricate and detailed parts. Molding techniques, including resin transfer molding (RTM) and vacuum bagging, contribute to the high quality and consistency of the finished products. Rigorous quality control measures are implemented throughout the process to maintain exacting standards and ensure each part meets the required specifications.

Prototyping and Testing

Prototyping is a crucial step in the development of custom carbon fiber parts. It allows designers to create and test preliminary versions of the parts, identifying any potential issues before full-scale production. Rigorous testing procedures, such as stress testing and environmental simulations, are conducted to ensure that the parts meet all performance and durability standards. This thorough approach guarantees that the final custom carbon fiber parts are reliable and effective for their intended applications.

Applications of Custom Carbon Fiber Parts

Aerospace and Drones

Custom carbon fiber parts are extensively used in aerospace and drone applications due to their lightweight and high-strength properties. In aerospace, carbon fiber components contribute to significant weight reductions, enhancing fuel efficiency and payload capacity. For drones, custom carbon fiber frames improve flight stability and durability. For instance, advanced drones used in surveying and mapping benefit from carbon fiber’s lightweight structure, which allows for longer flight times and better maneuverability.

Automotive and Motorsports

In the automotive and motorsports industries, custom carbon fiber parts play a crucial role in enhancing both performance and aesthetics. Carbon fiber body panels and components reduce vehicle weight, resulting in improved acceleration, handling, and fuel efficiency. High-performance sports cars, such as those used in racing, often feature custom carbon fiber parts to achieve competitive advantages. A notable example is the use of carbon fiber in Formula 1 cars, where every gram saved can lead to a significant performance boost.

Sports and Recreation

Custom carbon fiber parts offer numerous benefits in sports and recreational equipment. In cycling, carbon fiber frames and components provide a perfect balance of strength and lightness, allowing cyclists to achieve higher speeds with less effort. Tennis and badminton racquets made from carbon fiber offer superior control and power. High-performance sports gear, such as professional-grade bicycles and racquets, often utilizes custom carbon fiber parts to maximize performance and durability, providing athletes with a competitive edge.

Choosing the Right Supplier for Custom Carbon Fiber Parts

Expertise and Experience

Selecting a supplier with extensive expertise in carbon fiber is crucial for ensuring high-quality custom parts. Experienced suppliers bring a wealth of knowledge and technical skills, which are essential for producing precise and reliable components. Key factors to consider when choosing a supplier include their portfolio of past projects and customer reviews. A strong track record of successful projects and positive feedback from clients indicates a supplier’s capability and reliability.

Customer Reviews

Customer reviews provide valuable insights into the quality and reliability of custom carbon fiber parts. Positive feedback from satisfied clients can reinforce your decision to choose a particular supplier. Look for reviews that highlight aspects such as the durability, performance, and aesthetic appeal of the carbon fiber parts. Testimonials that mention excellent customer service and support can also be a good indicator of a reliable supplier.

Conclusion

Choosing custom carbon fiber parts offers numerous benefits, including exceptional strength-to-weight ratio, durability, and aesthetic appeal. These parts are tailored to meet specific project requirements, ensuring optimal performance and functionality. Customization allows for unique designs and precise specifications, making carbon fiber parts ideal for a wide range of applications, from aerospace and automotive to sports equipment.

By opting for custom carbon fiber parts, you ensure that your project benefits from the latest advancements in material science and engineering. Whether you need lightweight components for drones or high-performance parts for motorsports, custom carbon fiber offers the versatility and quality required to excel.

Consider integrating custom carbon fiber parts into your next project to experience their unparalleled advantages. For more information or to discuss your specific needs, please contact us or visit our website to explore our range of custom carbon fiber solutions, including carbon fiber sheets, carbon fiber tubes, and carbon fiber cutting services.

![[object Object]](https://carbonfiber-cnc.com/wp-content/uploads/2023/05/wendy.jpg)