Introduction

Carbon fiber has become an essential material in many industries due to its unique properties and versatile applications. It is known for its high strength and low weight, revolutionizing fields such as aerospace, automotive, sports, and consumer goods. As a material composed of thin, strong crystalline filaments of carbon, it has set new standards in engineering and design.

Understanding Carbon Fiber

Definition and Composition

Carbon fiber consists of thin, strong crystalline filaments of carbon atoms. These atoms are bonded together in a pattern that forms a fiber approximately 5-10 micrometers in diameter. The most common precursor used in creating carbon fiber is polyacrylonitrile (PAN), although pitch and rayon can also be used. The resulting fibers are woven into fabric or combined with a resin to form a composite material, which is then molded into various shapes and forms.

History and Development

The development of carbon fiber dates back to the 1950s and 1960s, initially driven by aerospace applications requiring a high strength-to-weight ratio. Early advancements by companies like Royal Aircraft Establishment and Rolls-Royce in the UK and the United States paved the way for broader usage. Over the decades, improvements in manufacturing processes, such as the PAN method, have made carbon fiber more cost-effective and accessible, expanding its applications into automotive, sports, and industrial sectors.

| Year | Milestone |

|---|---|

| 1860 | Sir Joseph Swan creates the first carbon filament for incandescent light bulbs. |

| 1958 | Roger Bacon produces the first high-performance carbon fibers at Union Carbide. |

| 1963 | Rolls-Royce, in partnership with the Royal Aircraft Establishment and others, creates the first high-strength carbon fiber composites. |

| 1969 | The first commercial carbon fiber, known as T300, is produced by Toray Industries in Japan. |

| 1970s | Aerospace industry begins widespread use of carbon fiber composites for aircraft parts. |

| 1980s | Carbon fiber sees expanded use in sports equipment, such as tennis rackets and golf clubs. |

| 1990s | Introduction of PAN-based carbon fibers, improving strength and cost-efficiency. |

| 2000s | Carbon fiber becomes a key material in the automotive industry for lightweight components. |

| 2010s | Innovations in carbon fiber manufacturing processes lead to reduced costs and increased adoption in various industries, including wind energy and consumer electronics. |

| 2020s | Advances in recycling methods and sustainability efforts enhance the environmental profile of carbon fiber. |

Properties of Carbon Fiber

Physical Properties

Carbon fiber’s most notable physical property is its high strength-to-weight ratio. It is five times stronger than steel yet significantly lighter, making it an ideal material for applications where weight reduction is critical without compromising strength. Additionally, carbon fiber has a low density, which contributes to its lightweight nature.

| Material | Tensile Strength (MPa) | Density (g/cm³) | Strength-to-Weight Ratio (MPa/(g/cm³)) |

|---|---|---|---|

| Carbon Fiber | 3500 – 6000 | 1.6 | 2187.5 – 3750 |

| Steel | 400 – 800 | 7.8 | 51.3 – 102.6 |

| Aluminum | 250 – 600 | 2.7 | 92.6 – 222.2 |

Mechanical Properties

Carbon fiber has excellent tensile strength and rigidity. It can withstand substantial stress and strain without breaking, making it suitable for high-stress environments. It also has good fatigue resistance, meaning it can endure repeated loading and unloading cycles without significant degradation.

Thermal and Chemical Properties

Carbon fiber has high-temperature tolerance and is resistant to thermal expansion, maintaining its shape and strength even under extreme temperatures. It is also highly resistant to corrosion and chemical damage, extending its lifespan in various applications.

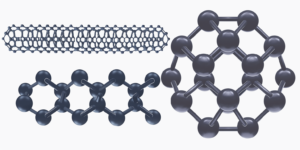

Types of Carbon Fiber

Different Grades

Carbon fibers are classified into different grades based on their modulus and strength. Standard modulus fibers are the most common, offering a balance of performance and cost. Intermediate modulus fibers provide higher stiffness, while high modulus fibers offer maximum rigidity for specialized applications.

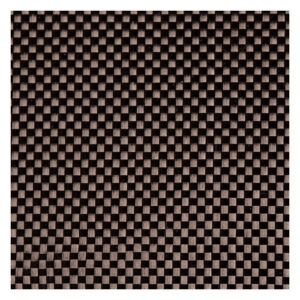

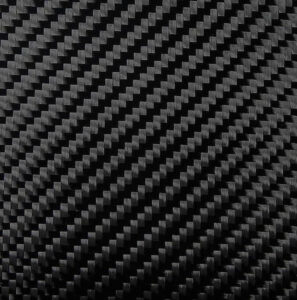

Weave Patterns

Carbon fiber fabrics come in various weave patterns, each offering unique characteristics. The most common patterns include:

Plain Weave: Known for its uniform appearance and stability.

Twill Weave: Offers better drapability and a distinctive visual texture.

Surface Treatments

To enhance bonding with resins and improve performance, carbon fibers often undergo surface treatments. Common treatments include sizing, which applies a protective coating to improve handling and processing, and plasma treatment, which enhances bonding characteristics.

Manufacturing Process of Carbon Fiber

Step-by-Step Overview

- Polymerization: The precursor material, usually PAN, is polymerized to form long-chain molecules.

- Spinning: The polymer is spun into fibers and stretched to align the molecular chains.

- Stabilization: The fibers are heated to make them heat-resistant.

- Carbonization: The stabilized fibers are heated to high temperatures, expelling non-carbon atoms and leaving pure carbon fibers.

- Surface Treatment: The fibers are treated to improve bonding with resins.

- Sizing: A protective coating is applied to the fibers to enhance handling and processing.

Key Technologies and Innovations

Advancements in carbon fiber manufacturing include automated production techniques, new precursor materials, plasma oxidation, and microwave-assisted carbonization. These innovations improve efficiency, reduce costs, and enhance fiber properties.

Applications of Carbon Fiber

Aerospace and Aviation

In aerospace, carbon fiber is used extensively in aircraft structures and components. Its high strength-to-weight ratio improves fuel efficiency and performance while reducing overall weight.

Automotive Industry

In the automotive sector, carbon fiber is used to manufacture lightweight parts that enhance vehicle performance and fuel efficiency. Components such as body panels, drive shafts, and interior trim benefit from carbon fiber’s strength and lightweight nature.

Sports and Recreation

Carbon fiber is popular in sports equipment due to its strength and lightweight properties. Bicycles, tennis rackets, and golf clubs are common examples of sporting goods that utilize carbon fiber for improved performance and durability.

Industrial and Civil Engineering

In construction and civil engineering, carbon fiber is used for reinforcing materials and structures. It is employed in retrofitting and strengthening concrete, steel, and masonry structures, providing enhanced durability and lifespan.

Consumer Goods

Carbon fiber finds applications in various consumer goods, including electronics, medical devices, and luxury items. Its aesthetic appeal and performance characteristics make it a desirable material for high-end products.

Advantages and Disadvantages of Carbon Fiber

| Advantages | Disadvantages |

|---|---|

| High Strength-to-Weight Ratio: Carbon fiber is much stronger and lighter than many other materials, including steel and aluminum. | High Cost: The manufacturing process is expensive, making the material costly. |

| High Stiffness: It has high rigidity, making it ideal for structural applications. | Brittleness: Carbon fiber can be brittle and may fracture under certain conditions. |

| Corrosion Resistance: Carbon fiber does not rust or corrode, making it suitable for harsh environments. | Manufacturing Complexity: The manufacturing process is complex and requires specialized knowledge and equipment. |

| Fatigue Resistance: It maintains its properties over a long period under cyclic loading conditions. | Difficulty in Repair: Repairing damaged carbon fiber structures can be challenging and often requires professional expertise. |

| Thermal Stability: It has low thermal expansion, maintaining dimensional stability across a wide temperature range. | Limited Recyclability: Recycling carbon fiber is difficult and not as straightforward as metals. |

| Design Flexibility: Carbon fiber can be molded into complex shapes, offering high design versatility. | Sensitivity to Impact: While strong, carbon fiber can be sensitive to sharp impacts and point loads. |

Future of Carbon Fiber

Emerging Trends

The future of carbon fiber is promising, with continuous innovations in production techniques and new applications emerging across various industries. Efforts to reduce manufacturing costs and improve properties will likely drive further adoption. Integration with advanced materials, increased use in consumer electronics, and growth in the automotive sector are key trends to watch.

Sustainability Efforts

As environmental concerns grow, there is a significant push towards sustainable production methods and recycling initiatives. Researchers are exploring eco-friendly processes and lifecycle analyses to minimize the environmental impact of carbon fiber production and use. Advances in recycling technologies are enabling the recovery and reuse of carbon fibers from composite materials, reducing waste and lowering the environmental footprint.

Conclusion

Summary of Key Points

Carbon fiber is a remarkable material known for its exceptional strength, lightweight, and versatility. It has revolutionized multiple industries and continues to push the boundaries of engineering and design. We explored its properties, types, manufacturing process, applications, advantages, and disadvantages, providing a comprehensive understanding of why carbon fiber is so crucial in modern technology and industry.

Final Thoughts

The ongoing advancements in carbon fiber technology and the increasing focus on sustainability indicate a promising future for this material. As innovations continue to emerge and sustainable practices become more widespread, carbon fiber is poised to play an even more significant role in various industries, contributing to technological progress and environmental stewardship.

![[object Object]](https://carbonfiber-cnc.com/wp-content/uploads/2023/05/wendy.jpg)