Introduction

Carbon fiber is valued for its strength, lightweight properties, and versatility. It is widely used in industries such as aerospace, automotive, and sports. Two main carbon fiber textures are twill weave and plain weave. Understanding the differences between these weaves helps you choose the right one for your needs.

Understanding Carbon Fiber Weaves

Carbon fiber weaves are patterns formed by interlacing strands. These patterns affect the material’s performance and appearance. The two common patterns are twill and plain weaves. Knowing these patterns is essential for selecting the right carbon fiber for your projects.

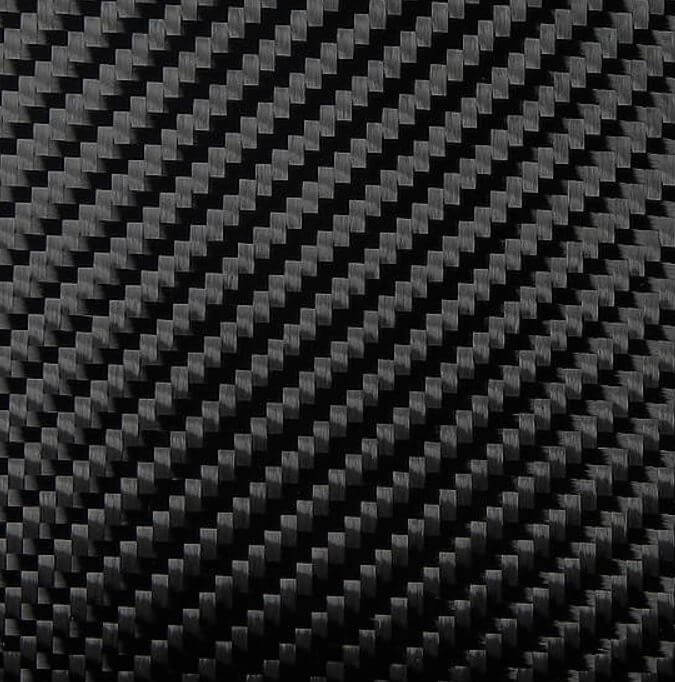

Twill Weave

Characteristics of Twill Weave

Twill weave has a diagonal pattern. The weft yarn passes over one or more warp yarns and then under two or more warp yarns. This creates a distinctive diagonal ribbing effect.

Advantages of Twill Weave

Twill weave is flexible and easy to shape. It conforms to complex curves, making it ideal for automotive body panels and sports equipment. Twill weave also has a higher strength-to-weight ratio.

Applications of Twill Weave

Twill weave is used in applications requiring intricate shapes and high strength. Examples include car parts, bike frames, and high-performance sports gear.

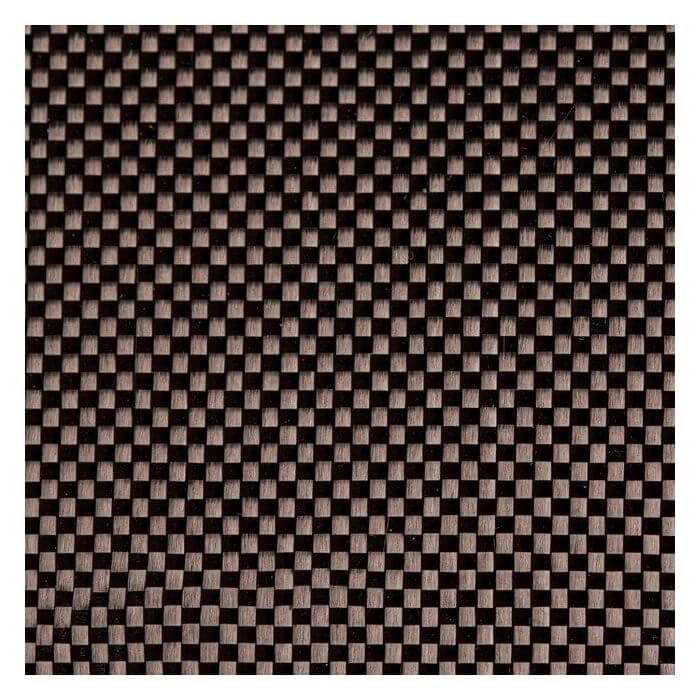

Plain Weave

Characteristics of Plain Weave

Plain weave, or tabby weave, is the simplest pattern. It features an over-under interlacing of weft and warp yarns, creating a checkerboard appearance.

Advantages of Plain Weave

Plain weave is stable and uniform, offering consistent strength. It is easier to manufacture and often more affordable.

Applications of Plain Weave

Plain weave is used in structural components and aerospace parts. It provides excellent strength and durability for various projects.

Performance Comparison

Durability and Strength

Both weaves are strong, but twill weave has a slight edge in distributing stress evenly. Twill is also more flexible and easier to mold into complex shapes.

Aesthetic Differences

Twill weave’s diagonal pattern is visually appealing, often preferred for visible applications. Plain weave’s checkerboard pattern is classic and understated.

Cost Considerations

Cost Differences

Twill weave is usually more expensive due to its complex manufacturing process. Plain weave is more cost-effective, offering a good balance of performance and affordability.

Choosing Based on Cost

When choosing, consider both initial cost and specific application needs. The right weave can enhance performance and longevity.

Choosing the Right Weave for Your Needs

Factors to Consider

Select the appropriate weave based on application, budget, and aesthetics. For intricate shapes and high strength, choose twill weave. For stability and cost efficiency, choose plain weave.

Recommendations

Twill weave is ideal for high-performance and visible applications. Plain weave is suitable for structural and cost-sensitive projects. Evaluate your project’s needs to make the best choice.

Conclusion

Both twill and plain weave carbon fibers have unique advantages. Twill weave offers flexibility and a pleasing pattern, while plain weave provides uniform strength and cost efficiency. Understanding these differences helps you choose the right carbon fiber for your projects, ensuring optimal performance and value.

![[object Object]](https://carbonfiber-cnc.com/wp-content/uploads/2023/05/wendy.jpg)