Introduction

Carbon fiber plates have become increasingly popular due to their unique properties and diverse applications. Understanding how they compare to traditional materials like steel, aluminum, and wood is crucial for industries seeking materials that offer a superior balance of strength, weight, and durability. This article explores the key differences, benefits, and considerations when choosing carbon fiber plates over traditional materials.

The Basics of Carbon Fiber Plates

What Are Carbon Fiber Plates?

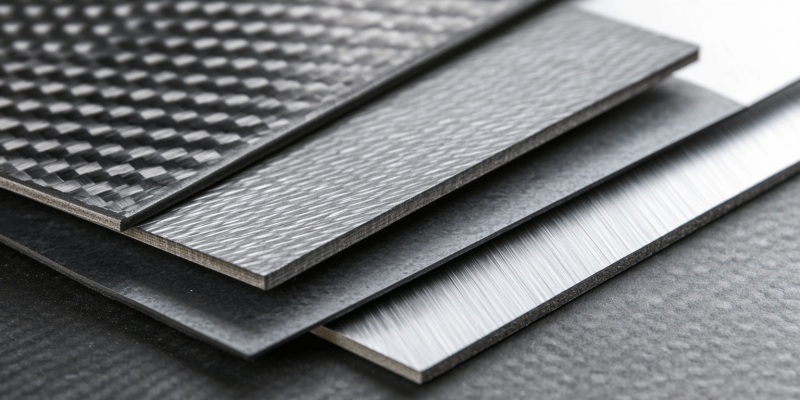

Carbon fiber plates are composite materials made from carbon fibers embedded in a polymer matrix. These fibers, known for their exceptional strength-to-weight ratio, are woven together and bonded with resin to form rigid plates. The manufacturing process involves layering the fibers in specific orientations to maximize strength and durability, followed by curing under heat and pressure.

Key Properties

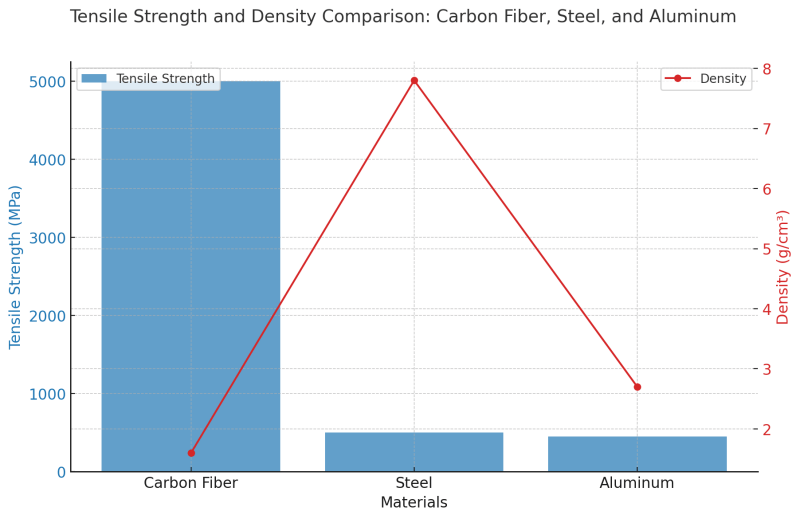

- High Tensile Strength: Carbon fiber plates can outperform steel in terms of tensile strength while being much lighter.

- Low Weight: Significantly lighter than metals like steel and aluminum.

- Excellent Fatigue Resistance: Carbon fiber plates maintain their strength and structural integrity under repeated stress.

- Superior Stiffness: The rigidity of carbon fiber plates makes them ideal for applications requiring precision and minimal flex.

Strength and Durability Comparison

Carbon Fiber vs. Steel and Aluminum

Carbon fiber plates offer a tensile strength that can surpass steel while being significantly lighter. In applications like aerospace and automotive, using carbon fiber plates reduces the overall weight, enhancing fuel efficiency and performance.

Corrosion Resistance

Unlike aluminum, which is prone to corrosion, carbon fiber plates are highly resistant to environmental factors, extending their lifespan and reducing maintenance costs. Real-world examples include their use in high-performance vehicles and aircraft.

Weight and Performance Benefits

Importance of Weight Reduction

Weight reduction is crucial in many industries, and carbon fiber plates excel in this aspect. Compared to traditional materials, carbon fiber plates are much lighter, improving performance and efficiency.

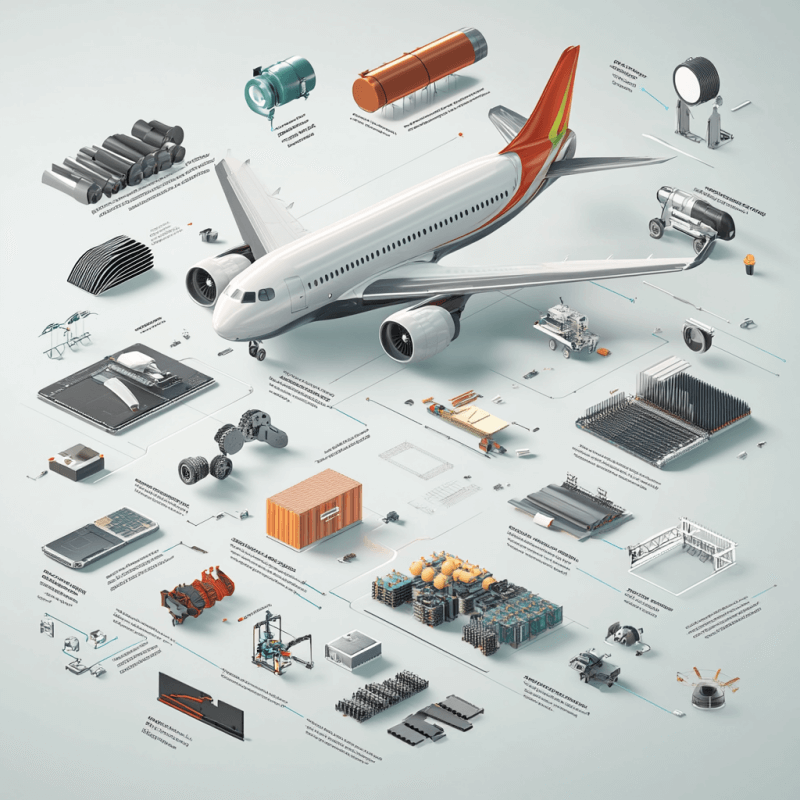

Industry Examples

In the automotive sector, lighter materials contribute to faster acceleration, better handling, and reduced fuel consumption. Sports equipment like tennis rackets and bicycles also benefit from carbon fiber’s lightweight nature, showing significant performance improvements.

Cost Considerations and Longevity

Initial vs. Long-Term Costs

While the initial cost of carbon fiber plates can be higher than traditional materials, the long-term benefits often outweigh the upfront investment. Carbon fiber plates require less maintenance and have a longer lifespan, leading to cost savings over time.

Case Study: Marine Industry

In the marine industry, using carbon fiber plates in boat hulls and components improves performance and reduces the need for frequent repairs. This longevity and reliability make carbon fiber plates a cost-effective solution in the long run.

Versatility and Applications

Customization and Flexibility

Carbon fiber plates are highly versatile and can be customized to meet specific requirements. They are used in a wide range of industries, from aerospace and automotive to sports equipment and consumer electronics.

Industry Applications

In the drone industry, carbon fiber plates provide the necessary strength and lightweight characteristics for optimal flight performance. In the RC car and sim racing sectors, they enhance durability and precision, catering to the demands of enthusiasts and professionals alike.

Environmental Impact

Sustainability Considerations

Carbon fiber plates offer environmental advantages. While their manufacturing process can be energy-intensive, advances in technology are making it more sustainable. Additionally, their long lifespan and reduced maintenance requirements contribute to a lower environmental footprint over time.

Lifecycle Analysis

Lifecycle analysis shows that carbon fiber plates can be more environmentally friendly compared to traditional materials, especially considering their recyclability and disposal. Innovations in sustainable carbon fiber production further enhance their eco-friendliness.

Conclusion

Carbon fiber plates offer numerous advantages over traditional materials, including superior strength, reduced weight, increased durability, and long-term cost savings. Their versatility and environmental benefits make them a preferred choice in various industries. Understanding these differences is crucial for making informed decisions that optimize performance and efficiency. As technology advances, the potential for carbon fiber plates will continue to grow, promising even greater benefits and applications in the future.

![[object Object]](https://carbonfiber-cnc.com/wp-content/uploads/2023/05/wendy.jpg)