Choosing the right material for your project is crucial. It impacts performance, durability, cost, and sustainability. Carbon fiber and aluminum are two popular choices, each with unique properties. This article compares these materials to help you make an informed decision.

Understanding Carbon Fiber and Aluminum

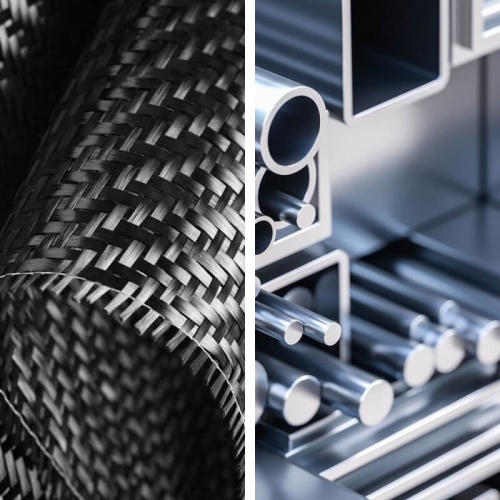

What is Carbon Fiber?

Carbon fiber is a high-strength, lightweight material made of thin strands of carbon atoms. These strands are woven into fabric and combined with epoxy resin to create a composite. Carbon fiber is known for its excellent strength-to-weight ratio and is used in aerospace, sports equipment, automotive parts, and medical devices.

What is Aluminum?

Aluminum is a versatile, lightweight metal known for its malleability and corrosion resistance. Extracted from bauxite ore, aluminum is widely used in construction, automotive manufacturing, electronics, and packaging. It’s appreciated for its strength, light weight, and ease of use.

Key Differences

- Strength and Weight: Carbon fiber is stronger and lighter than aluminum, making it ideal for weight-sensitive applications.

- Durability: Carbon fiber is more resistant to corrosion and environmental damage. Aluminum is also durable but can corrode under certain conditions.

- Cost: Aluminum is cheaper and more abundant than carbon fiber.

- Manufacturing: Aluminum is easier and cheaper to manufacture, while carbon fiber requires specialized processes.

- Applications: Carbon fiber is used in high-performance industries like aerospace and sports. Aluminum is used in construction, automotive, and consumer products.

Strength and Durability Comparison

Tensile Strength

Carbon fiber has a tensile strength of up to 500 ksi, much higher than aluminum’s 70 ksi. This makes carbon fiber suitable for high-stress applications without adding weight.

Durability and Wear Resistance

Carbon fiber is highly resistant to fatigue and environmental factors. It does not rust or degrade, maintaining its integrity over time. Aluminum, while resistant to corrosion due to its oxide layer, can still degrade under harsh conditions.

Applications Needing Strength and Durability

- Aerospace: Aircraft components benefit from carbon fiber’s strength and light weight, improving fuel efficiency and performance.

- Automotive Racing: Carbon fiber parts enhance speed and handling in high-performance cars.

- Sports Equipment: Lightweight and strong, carbon fiber is ideal for bicycles, rackets, and golf clubs.

- Marine Applications: Carbon fiber is used for performance hulls and masts in racing yachts, while aluminum is common in commercial boats.

Weight and Performance

Significance of Weight

Weight is crucial in many industries. Reducing weight improves speed, fuel efficiency, and overall performance. Lightweight materials also reduce energy consumption and operational costs.

Comparing Weights

Carbon fiber is significantly lighter than aluminum. Its density is about 1.6 g/cm³ compared to aluminum’s 2.7 g/cm³. This makes carbon fiber ideal for applications where every gram counts.

Industry Impacts

- Aerospace: Carbon fiber’s lightweight properties lead to better fuel efficiency and longer flight ranges.

- Automotive: Lighter vehicles improve fuel economy and performance. Carbon fiber enhances speed and handling in high-performance cars.

- Sports: Lightweight sports equipment, like carbon fiber bicycles and tennis rackets, improves performance and reduces fatigue.

Cost and Budget Considerations

Cost Breakdown

Carbon fiber is more expensive than aluminum due to complex production processes. Aluminum is more affordable and easier to produce.

Factors Affecting Costs

- Raw Material Cost: Carbon fiber’s production involves high energy use and expensive precursor materials. Aluminum is abundant and cheaper to refine.

- Manufacturing: Carbon fiber requires specialized techniques, making production more costly. Aluminum is easier to work with, reducing manufacturing expenses.

- Long-Term Maintenance: Carbon fiber’s durability lowers long-term maintenance costs. Aluminum requires more maintenance in corrosive environments.

Budget Constraints

For cost-sensitive projects, aluminum is often the preferred choice. It’s suitable for large-scale applications where budget is a priority. For high-performance needs, carbon fiber’s benefits justify its higher costs.

Ease of Manufacturing and Customization

Working with Carbon Fiber and Aluminum

Aluminum is easier to shape, cut, and weld. Carbon fiber requires specialized processes like lay-up and autoclaving, which are more complex and time-consuming.

Customization Options

- Aluminum: Easily customizable through extrusion, casting, machining, and welding. Surface treatments enhance appearance and durability.

- Carbon Fiber: Customizable through molding, cutting, and layering. Ideal for applications needing tailored designs and optimized strength.

Beneficial Projects

- Automotive Parts: Aluminum’s ease of manufacturing suits mass-produced components. Carbon fiber enhances high-performance car parts.

- Consumer Electronics: Aluminum casings are durable and aesthetically pleasing. Carbon fiber offers a high-tech look for premium products.

- Sporting Goods: Aluminum is used in customizable bicycle frames. Carbon fiber is preferred for high-performance sports equipment.

- Aerospace: Aluminum suits structural parts. Carbon fiber’s strength and weight benefits critical components like wing spars.

Environmental Impact

Production Footprint

Carbon fiber production is energy-intensive, resulting in a high carbon footprint. Aluminum production also has significant environmental impacts, primarily from bauxite extraction and electrolysis.

Recyclability and Sustainability

- Carbon Fiber: Recycling is challenging but improving with new techniques. Limited recyclability compared to metals.

- Aluminum: Highly recyclable, requiring less energy for recycling. More sustainable due to efficient recycling processes.

Future Trends

- Carbon Fiber: Research focuses on bio-based precursors and renewable energy to reduce the carbon footprint.

- Aluminum: The industry is adopting renewable energy, improving recycling efficiency, and developing low-carbon production techniques.

Real-World Applications and Case Studies

Case Studies

- Boeing 787 Dreamliner (Carbon Fiber): Reduces weight by 20%, improving fuel efficiency and performance.

- Tesla Model S (Aluminum): Aluminum body and chassis enhance range and performance while maintaining safety.

Benefits and Challenges

- Carbon Fiber (Boeing 787): Benefits include weight reduction and durability. Challenges include high cost and complex manufacturing.

- Aluminum (Tesla Model S): Benefits include cost-effectiveness and ease of manufacturing. Challenges include lower strength-to-weight ratio and corrosion susceptibility.

Supporting Data

- Boeing 787: Consumes 20% less fuel than traditional aircraft, reducing operating costs and emissions.

- Tesla Model S: Achieves over 370 miles on a single charge, praised for performance and efficiency.

Pros and Cons Summary

Carbon Fiber

Pros:

- High strength-to-weight ratio

- Excellent durability

- High customizability

- Aesthetic appeal

Cons:

- High cost

- Complex manufacturing

- Limited recyclability

Aluminum

Pros:

- Cost-effective

- Easy to manufacture

- Highly recyclable

- Good corrosion resistance

Cons:

- Lower strength-to-weight ratio

- More susceptible to fatigue

- Heavier than carbon fiber

Quick-Reference Table

| Feature | Carbon Fiber | Aluminum |

|---|---|---|

| Strength-to-Weight Ratio | High | Moderate |

| Durability | Excellent (resistant to fatigue) | Good (susceptible to fatigue) |

| Weight | Very Light | Lightweight, but heavier |

| Cost | High | Moderate |

| Manufacturing Complexity | High (specialized processes) | Low (easily machined) |

| Customizability | High (tailored for needs) | High (variety of techniques) |

| Recyclability | Moderate (advancements ongoing) | High (efficient recycling) |

| Corrosion Resistance | Excellent | Good |

| Aesthetic Appeal | High-tech, premium look | Conventional, customizable |

Conclusion

Recap

We compared carbon fiber and aluminum in terms of strength, durability, weight, cost, manufacturing, environmental impact, and real-world applications. Carbon fiber excels in high-performance, lightweight, and durable applications but is more expensive and complex to manufacture. Aluminum is versatile, cost-effective, and easy to work with but has a lower strength-to-weight ratio.

Final Recommendations

- High-Performance Applications: Choose carbon fiber for projects where performance, weight, and durability are critical.

- Cost-Sensitive Projects: Opt for aluminum for budget-friendly applications.

- Custom Designs: Both materials offer customization benefits, depending on the project’s needs.

Consider Your Needs

When selecting between carbon fiber and aluminum, consider your project’s specific requirements and priorities. Evaluate factors like strength, weight, cost, durability, and environmental impact. The best material choice will align with your project’s goals and constraints, ensuring optimal performance and cost-efficiency.

By understanding the unique attributes of carbon fiber and aluminum, you can make an informed decision that meets your project’s needs.

![[object Object]](https://carbonfiber-cnc.com/wp-content/uploads/2023/05/wendy.jpg)