Introduction

Carbon fiber plates are widely used in various industries due to their strength and lightweight properties. However, working with carbon fiber requires precision and proper techniques to maintain its integrity. This guide provides comprehensive steps on cutting, drilling, and shaping carbon fiber plates safely and effectively.

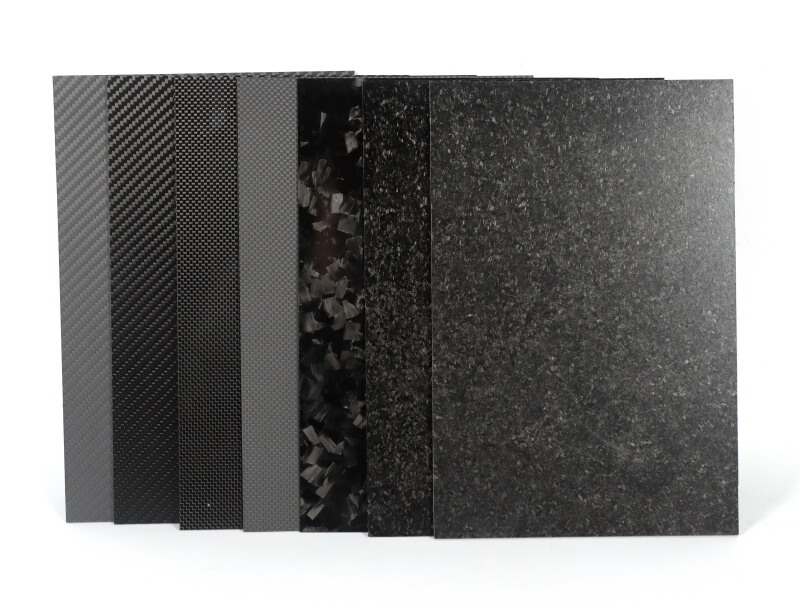

Understanding Carbon Fiber Plates

Carbon fiber plates are made of thin, strong carbon filaments woven together and bound with resin. They are known for their high strength-to-weight ratio and resistance to temperature changes. Common applications include aerospace, automotive, and sports equipment.

Essential Tools and Safety Equipment

To work with carbon fiber plates, you’ll need specific tools and safety gear:

- Tools: Diamond blades for cutting, carbide drill bits for drilling, and various sanding tools.

- Safety Gear: Gloves, masks, and goggles to protect from harmful dust.

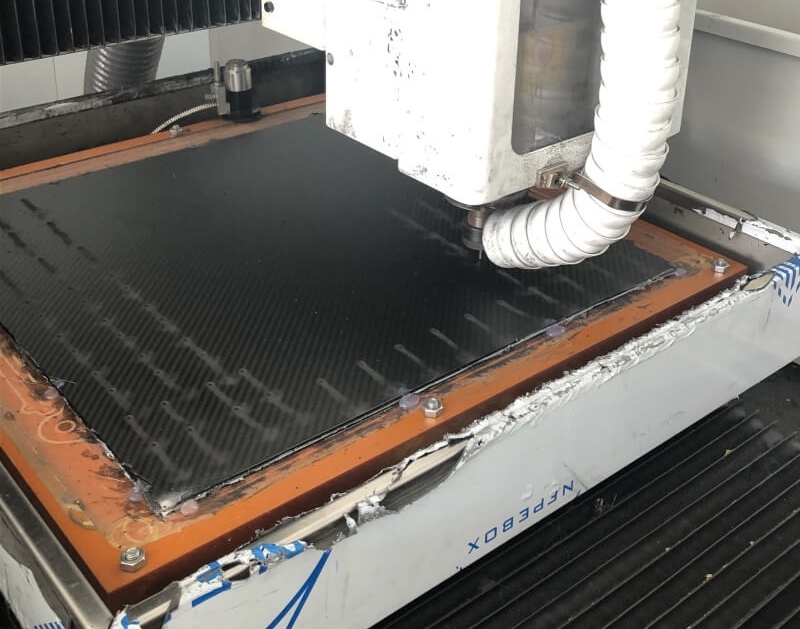

Cutting Carbon Fiber Plates

Preparation Steps Before Cutting

- Mark and Measure: Accurately mark and measure the plate.

- Secure the Plate: Firmly clamp the plate to prevent movement.

Recommended Cutting Techniques

- Straight Cuts: Use a wet saw with a diamond blade to reduce dust and prevent overheating.

- Curved Cuts: Use a jigsaw with a fine-toothed blade. Cut slowly to avoid fraying.

Step-by-Step Cutting Process

- Mark the Cutting Lines: Use a marker or tape to outline the cut.

- Secure the Plate: Use clamps to hold the plate steady.

- Cut the Plate: Use the appropriate saw, applying consistent pressure without forcing the blade.

- Smooth the Edges: Use fine sandpaper to smooth out any rough edges.

Drilling Carbon Fiber Plates

Preparation Steps Before Drilling

- Choose the Right Drill Bits: Select carbide drill bits for clean holes.

- Mark the Spots: Use a marker to precisely mark where you will drill.

- Secure the Plate: Clamp the plate securely to avoid any movement.

Recommended Drilling Techniques

- Low RPM Drilling: Drill at a low RPM to prevent overheating and delamination.

- Use Backing Material: Place a backing material behind the plate to support it and prevent splintering.

Step-by-Step Drilling Process

- Mark the Drilling Spots: Accurately mark the spots for drilling.

- Clamp the Plate: Secure the plate with clamps.

- Start Drilling: Begin at a low speed, gradually applying pressure to drill through the plate.

- Clean and Smooth the Holes: After drilling, clean the holes and use a deburring tool or fine sandpaper to smooth the edges.

Shaping and Sanding Carbon Fiber Plates

Preparation Steps Before Shaping and Sanding

- Plan the Shape: Outline the desired shape on the plate.

- Secure the Plate: Clamp the plate securely before shaping.

Recommended Shaping Techniques

- Use Files and Coarse Sandpaper: Start with files or coarse sandpaper to achieve the desired shape.

- Progress to Finer Grits: After shaping, use finer grits of sandpaper to smooth the surface.

Sanding for Smooth Edges and Finishes

- Start Coarse, Finish Fine: Begin with coarse sandpaper and work your way to finer grits for a smooth finish.

- Work in a Ventilated Area: Sand in a well-ventilated area or use a dust extraction system to minimize exposure to carbon fiber dust.

Common Mistakes to Avoid

- Overheating: Use appropriate speeds and tools to avoid overheating, which can damage the carbon fiber.

- Incorrect Tools: Ensure you’re using the correct tools designed for carbon fiber to prevent damage and achieve clean results.

- Skipping Safety Precautions: Always use safety gear, such as gloves, masks, and goggles, to protect yourself from carbon fiber dust and sharp edges.

Maintenance and Care for Carbon Fiber Products

- Cleaning: Use a damp cloth and avoid harsh chemicals.

- Repairing Minor Damages: Use an epoxy repair kit.

- Storage: Store in a cool, dry place away from direct sunlight to prevent UV damage.

Conclusion

Working with carbon fiber plates requires careful attention and proper techniques. By using the right tools and following the recommended steps for cutting, drilling, and shaping, you can achieve precise results while maintaining the material’s integrity. Always prioritize safety and proper maintenance to ensure the longevity of your carbon fiber products. For more advanced techniques or professional assistance, seek expert help.

This guide will help you work effectively and safely with carbon fiber plates, leading to successful projects.

![[object Object]](https://carbonfiber-cnc.com/wp-content/uploads/2023/05/wendy.jpg)