Autoclave Carbon Fiber Sheets & Custom CNC Solutions

Premium Structural Plates for Aerospace, Robotics, and Industrial Engineering

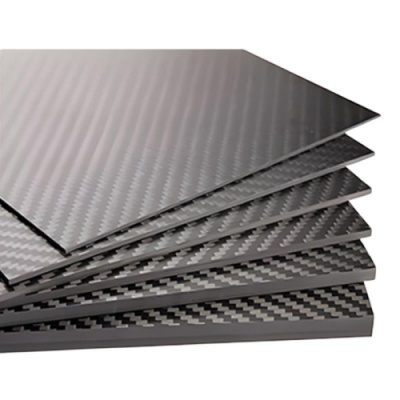

At iKabon, we don't just sell carbon fiber; we engineer performance. Unlike standard vacuum-bagged composites, our Autoclave and Compression Molded carbon fiber sheets deliver superior fiber consolidation, near-zero porosity, and maximum structural integrity.Manufactured using genuine Toray T300 and T700 fibers in an epoxy resin matrix, our plates are designed for high-stress applications requiring the ultimate stiffness-to-weight ratio. Whether you need a single prototype cut to ±0.05mm precision or a production run of 1,000 drone frames, iKabon is your direct manufacturing partner.Carbon Fiber Sheet Categories

Structural Carbon Fiber Plates (Rigid)

Engineered for Drone Frames, Chassis, and Industrial Cores. Our standard structural plates utilize a balanced layup to ensure flatness and dimensional stability.

Thickness: 0.2mm to 50mm (Customizable).

Finish: 3K Twill / Plain Weave (Matte or Glossy).

Core: 100% Solid Carbon Fiber (No fiberglass fillers)

Thick Carbon Fiber Sheets for CNC Machining (Carbon Fiber Blocks)

Thick carbon fiber sheets, often referred to as carbon fiber blocks, are designed for CNC milling, drilling, and complex three-dimensional machining. These materials are produced by laminating multiple layers of carbon fiber sheets to achieve greater thickness and structural integrity.

Compared to standard-thickness carbon fiber sheets, thick laminated formats provide increased machining allowance and are suitable for molds, fixtures, structural cores, and heavy-duty industrial components.

Aesthetics Meets Performance. Featuring a unique marble-like 3D texture, our Forged Carbon sheets are produced using chopped fiber molding. Ideal for luxury automotive interiors, knife handles, and consumer goods where visual impact is paramount.

Colored carbon fiber sheets enhance the visual appearance of standard carbon fiber sheets by incorporating colored fibers, surface layers, or special resin systems. These decorative carbon fiber sheets retain the lightweight and strength advantages of carbon fiber while offering greater design flexibility.

Colored carbon fiber sheets are widely used in automotive trims, RC projects, consumer products, and design-focused applications where visual impact matters.

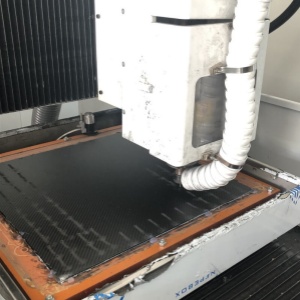

From CAD to Finished Part. Don’t risk delamination by cutting sheets yourself. Our in-house CNC machining service delivers ready-to-assemble parts.

Precision: ±0.05mm tolerance.

Capabilities: Chamfering, Countersinking, Engraving.

Files Accepted: DXF, DWG, STEP.

Technical Specifications: The Autoclave Advantage

Why choose iKabon? We utilize Autoclave Processing for our premium lines. This applies high heat and pressure (up to 6 bar) to the laminate, squeezing out air voids that weaken vacuum-bagged sheets.

Material Data Sheet (Typical Values)

| Property | Value / Specification |

| Fiber Brand | Toray T300 / T700 (Japan) |

| Resin System | High-Toughness Epoxy Matrix |

| Manufacturing Process | Autoclave & High-Pressure Mold Press |

| Standard Sizes | 400x500mm, 500x600mm, up to 8000x3000mm |

| Thickness Range | 0.2mm – 50mm |

| Thickness Tolerance | ±0.1mm (Standard) |

| CNC Machining Tolerance | ±0.05mm |

| Glass Transition Temp (Tg) | Standard 120°C (High-temp resins available upon request) |

| Fiber Volume Fraction | > 60% (High Density) |

| Surface Finish | 3K Twill / Plain / Forged / Unidirectional (UD) |

Industrial Applications

UAV & Drones: FPV racing frames, heavy-lift drone arms, and landing gear reinforcement.

Robotics: Lightweight manipulator arms and end-effectors to reduce motor strain and inertia.

Medical Devices: X-ray translucent tables and external fixation devices.

Automotive: Interior trim panels (Forged/Colored), structural chassis stiffeners, and battery enclosures.

Marine: Bulkheads and instrument panels.

What’s the Difference Between Carbon Fiber Sheets, Plates, Panels, Boards, and Blocks?

In the carbon fiber industry, terms such as sheets, plates, panels, boards, and blocks are often used interchangeably, which can be confusing for buyers and engineers. In most cases, carbon fiber sheets refer to flat laminated composite materials produced in controlled thicknesses and sizes.

“Plates” and “boards” are commonly alternative naming conventions used in different industries or regions, while “panels” often emphasize surface appearance or decorative use. Carbon fiber blocks usually describe thick laminated formats intended for CNC machining rather than thin sheet applications. Understanding these differences helps ensure the correct carbon fiber material is selected for each application.

Ready to Start Your Project?

Whether you need a standard stock plate or a complex CNC-machined component, iKabon delivers aerospace-grade quality with rapid turnaround times (2-15 days).

Attach your drawings or select your sheet size for pricing.

Carbon Fiber Sheets FAQ

The variety in carbon fiber sheets is due to differing manufacturing methods, fiber types, resin types, and weave patterns. These variations cater to specific strength, flexibility, and weight requirements for different applications.

Yes. We specialize in CNC routing. Simply send your .DXF or .STEP files for a quote. We use specialized diamond-coated tooling to ensure smooth edges without fraying or delamination.

We possess one of the largest presses in the region, capable of producing single sheets up to 8000mm x 3000mm (8×3 meters).

Yes, we can customize the thickness of carbon fiber sheets according to your project needs. We offer a range of standard thicknesses and can accommodate custom requests.

The suitability of a carbon fiber sheet for your project depends on your specific requirements like strength, flexibility, weight, and environmental resistance. Contact us, we can help determine the best fit.

The maximum temperature a carbon fiber sheet can withstand depends on the resin used. Most of our standard carbon fiber sheets can withstand temperatures up to approximately 120°C -180°C (248°F~356°F), but we can customize high temperature materials to withstand higher temperatures.

Vacuum bagging only applies ~1 bar of pressure, often leaving microscopic voids (air bubbles) inside the laminate. Autoclave processing applies up to 6 bar of pressure, crushing voids and compressing the fiber layers tightly. This results in a sheet that is stiffer, stronger, and has a perfect surface finish free of pinholes.

Yes, we offer carbon fiber cutting service since 2013. Just email us the drawings for a quotation.

Cutting carbon fiber sheets should be done with diamond-tipped tools or abrasive cutting wheels. If you want to know more about carbon fiber cutting, just email us. Safety equipment is crucial due to the fine, sharp fibers produced when cutting; a dust mask, eye protection, and gloves are recommended.

No. We support innovation at every stage. You can order a single custom-cut prototype or 5,000 units.