Introduction

Carbon fiber is renowned for its exceptional strength-to-weight ratio and versatility. It is commonly used in industries such as aerospace, automotive, and sports equipment. However, machining carbon fiber poses unique challenges that can impact both product quality and manufacturing efficiency. Understanding these challenges and knowing how to overcome them is crucial for anyone working with this advanced material.

In this article, we will explore the top five challenges encountered during the machining of carbon fiber and provide practical solutions to address each one. By implementing these strategies, manufacturers can improve tool life, enhance product quality, and ensure safer working conditions.

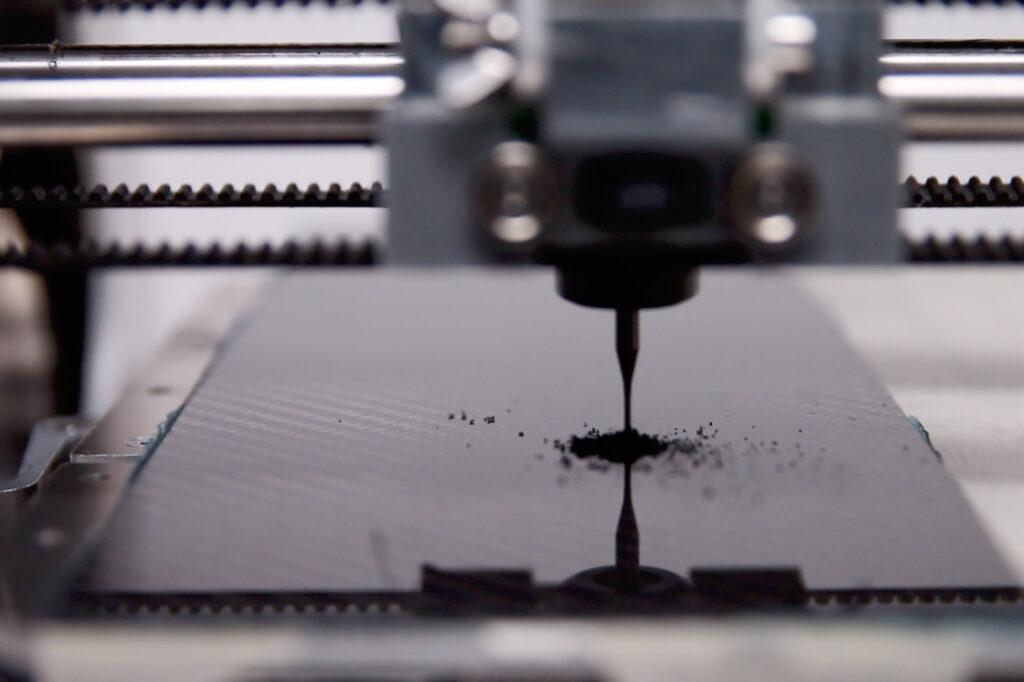

Challenge 1: Tool Wear and Damage

Understanding Tool Wear in Carbon Fiber Machining

One of the primary challenges in machining carbon fiber is the rapid wear and damage to cutting tools. Carbon fiber’s abrasive nature, due to its high hardness and the presence of sharp, brittle fibers, can quickly dull conventional tools. This results in increased tool wear, frequent tool changes, and higher operational costs.

Solutions for Minimizing Tool Wear

- Use Diamond-Coated or Carbide Tools: Diamond-coated tools are exceptionally hard and wear-resistant, making them ideal for machining abrasive materials like carbon fiber. Carbide tools with a high-quality finish also perform better than traditional steel tools.

- Optimize Cutting Speeds and Feeds: Properly adjusting the cutting speed and feed rate can significantly reduce tool wear. Lowering the cutting speed and adjusting the feed rate to match the tool’s capabilities can minimize the impact and friction between the tool and the material, extending the tool’s life.

- Regular Maintenance and Replacement Schedules: Implementing a regular maintenance schedule for tools, including frequent inspections and timely replacements, helps maintain machining efficiency and prevent unexpected downtime.

Challenge 2: Delamination and Fiber Pullout

Causes of Delamination and Fiber Pullout

Delamination and fiber pullout are common issues in machining carbon fiber, where layers of the composite material separate or individual fibers are pulled out from the matrix. These problems arise due to improper machining parameters, suboptimal tool selection, and the inherent brittleness of the material.

Preventive Measures and Techniques

- Optimize Machining Parameters: Adjusting the cutting speed, feed rate, and depth of cut is crucial in preventing delamination and fiber pullout. Using lower cutting speeds and moderate feed rates can reduce stress on the material, minimizing the risk of separation and fiber dislodgement.

- Use Sharp, High-Quality Tools: Employing sharp, high-quality tools specifically designed for carbon fiber can significantly reduce delamination and fiber pullout. Regularly replacing or sharpening tools maintains their effectiveness.

- Implement Suitable Machining Strategies: Techniques such as climb milling, where the tool rotates in the same direction as the feed, can reduce delamination compared to conventional milling. Experimenting with different strategies helps determine the best approach for specific applications.

Challenge 3: Dust and Health Hazards

Health Risks Associated with Carbon Fiber Dust

Machining carbon fiber generates fine dust particles that pose serious health risks if inhaled or come into contact with the skin. These particles can cause respiratory issues, skin irritation, and other long-term health problems. Ensuring the safety of workers in environments where carbon fiber machining occurs is paramount.

Effective Dust Management Solutions

- Installation of Proper Ventilation and Dust Extraction Systems: Effective dust extraction systems remove airborne particles from the workspace. High-efficiency particulate air (HEPA) filters capture fine carbon fiber dust, preventing it from spreading. Proper ventilation ensures that any residual dust is continuously removed, maintaining air quality.

- Use of Personal Protective Equipment (PPE): Providing workers with appropriate personal protective equipment, including masks or respirators, protective clothing, and safety goggles, is vital. Regular training on the proper use and maintenance of PPE enhances its effectiveness.

- Regular Cleaning and Maintenance of the Machining Area: Routine cleaning of the workspace prevents the accumulation of carbon fiber dust. Wet cleaning methods, such as mopping and wiping surfaces with damp cloths, help capture dust particles without dispersing them into the air. Regular maintenance of dust extraction systems and filters keeps them operating efficiently.

Challenge 4: Heat Generation and Thermal Damage

Impact of Heat on Carbon Fiber and Machining Tools

Excessive heat generation during the machining of carbon fiber can lead to thermal damage to both the material and the machining tools. This can result in resin degradation, fiber breakage, and compromised structural integrity. Additionally, heat can cause premature wear or failure of cutting tools.

Strategies for Controlling Heat Generation

- Use of Coolants and Lubricants: Applying coolants and lubricants can significantly reduce heat generated during machining. These substances help dissipate heat away from the cutting area, maintaining lower temperatures and preventing thermal damage.

- Optimization of Cutting Parameters: Adjusting cutting speeds, feed rates, and depths of cut can help manage heat generation. Lower cutting speeds and moderate feed rates reduce friction and heat buildup.

- Employing High-Speed Machining Techniques: High-speed machining (HSM) techniques, involving high spindle speeds and low feed rates, minimize the time the tool spends in contact with the material, reducing heat buildup. Using advanced, heat-resistant tools also helps manage thermal damage.

- Use of Heat-Resistant Tools: Selecting tools made from materials that can endure high temperatures, such as diamond-coated or carbide tools, can help manage thermal damage.

Challenge 5: Surface Finish and Precision

Achieving Desired Surface Finish in Carbon Fiber

Achieving a smooth and precise surface finish when machining carbon fiber is challenging due to the material’s unique properties. The fibers can cause fraying or splintering, while the resin can melt or chip away, resulting in a suboptimal finish.

Techniques for Improving Surface Finish

- Fine-Tuning Machining Parameters: Adjusting machining parameters such as cutting speed, feed rate, and depth of cut is essential for achieving a smooth surface finish. Lower cutting speeds and feed rates can reduce the risk of fraying and splintering.

- Use of High-Quality Finishing Tools: Utilizing specialized finishing tools designed for carbon fiber can enhance the surface finish. Tools with sharp, high-precision cutting edges ensure clean cuts, reducing surface imperfections. Regularly replacing or sharpening these tools maintains their effectiveness.

- Implementation of Post-Machining Processes: Post-machining processes such as sanding and polishing can improve the surface finish. Sanding with progressively finer grits smooths out rough areas left by machining. Polishing further enhances the surface quality, providing a smooth, aesthetically pleasing finish.

- Application of Protective Coatings: Applying protective coatings after machining can improve the surface finish and protect the material. Coatings such as clear epoxy or specialized sealants can fill in minor imperfections, providing a smoother surface and protection against environmental factors.

- Utilizing CNC Machining Techniques: CNC (Computer Numerical Control) machining offers high precision and control over the machining process. CNC machines provide consistent and repeatable surface finishes, ensuring high-quality results.

Conclusion

Recap of Key Challenges and Solutions

Machining carbon fiber presents several significant challenges, including tool wear and damage, delamination and fiber pullout, dust and health hazards, heat generation and thermal damage, and achieving a desired surface finish and precision. By understanding these issues and implementing targeted solutions, manufacturers can improve both the efficiency and quality of their machining processes.

Importance of Continuous Improvement and Adaptation

The field of carbon fiber machining is continually evolving, with new tools, techniques, and technologies emerging regularly. Continuous improvement and adaptation are essential for staying competitive and achieving the best results. Manufacturers should stay informed about the latest advancements in machining practices and invest in ongoing training for their teams.

Encouragement for Industry Best Practices

Adopting industry best practices is crucial for maintaining high standards in carbon fiber machining. This includes prioritizing worker safety, implementing proactive maintenance schedules, and striving for excellence in surface finish and precision. By sharing knowledge and collaborating with industry peers, manufacturers can contribute to the collective advancement of machining techniques.

In conclusion, overcoming the challenges of machining carbon fiber requires a combination of advanced tools, optimized processes, and a commitment to continuous improvement. By embracing these practices, manufacturers can enhance their capabilities, produce high-quality products, and maintain a safe and efficient working environment.

![[object Object]](https://carbonfiber-cnc.com/wp-content/uploads/2023/05/wendy.jpg)